Shenzhen, Guangdong Oct 15, 2025 (Issuewire.com) - YIBI Group, an established name in luxury hardware and precision metal components, is positioning itself as China Top Custom Stainless Steel Bag Hardware Manufacturer by integrating rigorous sustainability credentials such as GRS certification and RCS certification into its product offerings. Leveraging deep expertise in stainless steel and zirconia ceramic materials, as well as advanced PVD and plating techniques, YIBI is delivering high-end hardware solutionsespecially custom stainless steel bag frames, buckles, clasps, and connectorswith both aesthetic excellence and environmental accountability.

In an era when consumers and brands alike demand not only craftsmanship but credibility in sustainable sourcing, YIBIs dual focus on technical innovation and chain-of-custody discipline under GRS (Global Recycled Standard) sets it apart. Its stainless steel leather hardware is built for durability, corrosion resistance, non-oxidation, and long-term aesthetic stability, making it ideal for high-end handbags, belts, and wearable accessories.

Industry Outlook: Sustainability, Customization, and Metal InnovationSustainability & Certification as Market Imperative

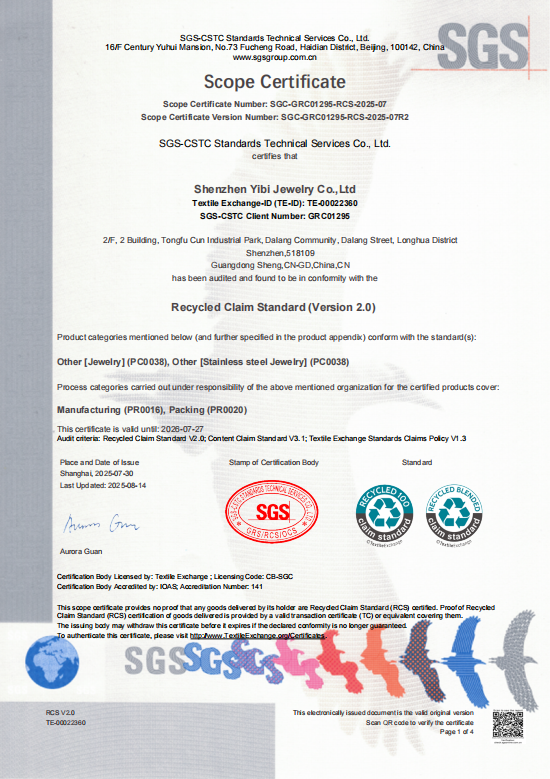

The luxury goods sector is undergoing a transformation: leading brands are seeking to embed verified sustainability credentials into every component, not just the fabrics or packaging. Both GRS(Global Recycled Standard) and RCS(Recycled Claim Standard) are such certifications that verify the use of recycled material and enforces a transparent chain of custody from source to final product.

Where many manufacturers claim eco-friendly status in marketing, true certified compliance requires rigorous audit, traceability, and ongoing verification steps that only a few hardware makers are capable of achieving. As fashion houses push sustainability goals deeper into their supply chains, hardware suppliers with robust certifications like GRS will become strategic gatekeepers to brand alignment.

Demand for Premium Metal Hardware in Apparel & Leather Goods

1.Rising expectations for functional elegance. As the frame bag and structured handbags regain visibility, the demand for customized metal hardware from hinges to locking mechanisms is rising. Brands no longer accept generic hardware; each piece is now part of the products visual signature.

2.Material sophistication. Stainless steel, zirconia ceramic, and advanced PVD finishes are becoming preferred choices because of their superior corrosion resistance, color stability, and scratch durability. YIBI itself promotes stainless steels environmental properties resistance to fading, oxidation, and long life cycles.

More On 360mediahub ::

- Acclaimed Chiropractor Howard Benedikt, DC, MS, DCBCN, Offers Comprehensive Health Solutions in New York City

- Daniel E. Wenger, Recognized by BestAgents.us as a 2025 Top Agent

- FaceSwapAI is a free AI-powered platform that enables users to swap faces in photos and videos quickly, offering high-quality results with intelligent enhancements in seconds.

- The Importance of CPSC 16 CFR 1201 Compliance in a Wholesale Tempered Glass Panels Factory

- Printify Reveals Which Hobbies Can Become Profitable Online Businesses in 2026

3.OEM/ODM relationships, not commodity supply. Brands increasingly demand hardware partners who can do more than parts. They want technical collaborators able to convert boutique sketches into mass-manufacturable metal components, integrate surface technologies, and manage quality across scales.

4.Precision meets scale. For frame-based bags and hardware-centric accessories, margin for dimensional deviation is near zero. A hinge must align to microns; a clasp must operate quietly and smoothly across thousands of cycles. Suppliers that can consistently deliver tight tolerances under full production are rewarded.

Given these forces, YIBIs strategy blending technical excellence with sustainability credentials is well-timed. Many brands are now filtering suppliers not only on cost and lead time, but on how well they align with ESG goals.

YIBIs Competitive Position: From Hardware Expert to Sustainable PartnerCompany Background & Certification Commitment

Founded with roots in hardware and metal processing, YIBI is headquartered in Shenzhen and has built a reputation as a hardware & jewelry OEM/ODM specialist. Its product portfolio emphasizes stainless steel and zirconia ceramic hardware, using advanced techniques such as metal injection molding (MIM) and ceramic injection molding (CIM). YIBI holds certifications including ISO9001, TS/16949, RCS, and now is advancing its commitment with GRS certification.

By formalizing the GRS certification, YIBI enables downstream brands to credibly claim recycled content even in their metal hardware components a rare assurance in a category where metal itself is typically assumed virgin. This certification underscores YIBIs ambition to lead not only in performance but in sustainability compliance.

Core Advantages & Technical Capabilities

- Deep domain in leather hardware: Over the years, YIBI has accumulated refined know-how in fitting, clasp, hinge, frame, and decorative hardware specifically tailored for luxury leather goods. This background gives it intimate understanding of tolerances, finishing expectations, and the functional stresses of day-to-day wear.

- Precision finishing from jewelry lineage: Drawing on its jewelry and precision metal heritage, YIBI applies micro-level polishing, plating (PVD, ionic, electroplating), and surface texture control that many hardware-only firms cannot match. This crafts a more refined visual feel, smooth touch action, and tighter consistency across batches.

- Strong materials and processes: YIBIs product lines span stainless steel buckles, connectors, bag clasps, zipper pulls, and frame hardware often incorporating zirconia ceramics for accent or hardness. They are capable of high-precision MIM/CIM production and post-sintering processes, making thin, strong, consistent parts.

- Full-value chain control: From raw material procurement and incoming testing to plating, inspection, and final assembly, YIBI maintains vertical integration, which helps assure lead time, consistency, and quality control.

- R&D & client collaboration: The firm works directly with brands in design-to-metal conversion, prototyping, 3D modeling, mechanical stress testing, and finish matching. This co-development model helps clients mitigate risk, accelerate time to market, and maintain design fidelity.

Application Scenarios & Product Highlights

- Custom stainless steel bag frames A flagship component for structured handbags and clutches. YIBI ensures hinge precision, closure alignment, and long-term fatigue resistance, all while maintaining refined surface finishes.

- Buckles and clips From belt buckles to bag adjusters, YIBI offers custom shapes, plating colors, and integration of zirconia ceramic inlays for scratch resistance.

- Zipper pulls, sliders & connectors Robust stainless steel hardware that matches bag bodies, designed to avoid corrosion, fading, or tarnishing.

- Decorative metal accents & logos Small badges and signature hardware pieces, finished to jewelry-grade aesthetic standards, suitable for integration on high-end leather goods.

Client Cases & Market Presence

Though specific brand names are often under NDA, YIBI has a strong track record supplying international luxury and designer labels. They have been multiple times recognized in industry directories as a reliable high-quality hardware vendor.

We have more than 15 years of experience in luxury hardware and precision metal parts, positioning them as a global OEM partner. YIBI is often listed as a trusted vendor in directories for jewelry, bag hardware, and precision MIM hardware.

Through its sustainability credentials and tchnical depth, YIBI is reinforcing its role as more than a supplier increasingly it acts as a strategic hardware partner to brands seeking traceable, high-performance, and design-faithful components.

A Forward Path: Sustainability, Precision & Partnership

YIBIs decision to publicize its GRS certification is more than a marketing milestone it signals a deliberate strategic pivot. In an ecosystem where brands must show credible sustainability along with premium experience, hardware suppliers will no longer be peripheral. YIBI seeks to be the go-to hardware partner for brands that prioritize both functional excellence and environmental accountability.

In the coming years, as recycled material traceability becomes more central to consumer trust, YIBIs layered investment combining stainless steel excellence, jewelry-grade finishing, and certified chain-of-custody discipline is likely to make it a benchmark in the industry.

For brands, designers, and stakeholders seeking a hardware collaborator that grasps both the art and responsibility of premium accessories, YIBI offers a rare alignment of skills, ethics, and execution. Its infrastructure, certification, and track record make it a compelling candidate in global supply chains.

For more information, visit YIBIs LinkedIn profile:

https://www.linkedin.com/company/yibi-group/

Source :Shenzhen Yibi Jewelry Co., Ltd

This article was originally published by IssueWire. Read the original article here.